- ProductsDassault SystemesSiemens PLMERP SystemsOur Products

- IndustriesMarineAerospaceMarine IndustriesIndustrialArchitectureEngineeringPharmaceuticalOil & GasNovel Technologies

Marine

The aerospace and military industries face an assortment of challenges. The sensitivity involved in verifying an airplane component is much more complex than a car’s or industrial machine’s component, and no expenses are spared for creating publishable information and documents

Aerospace

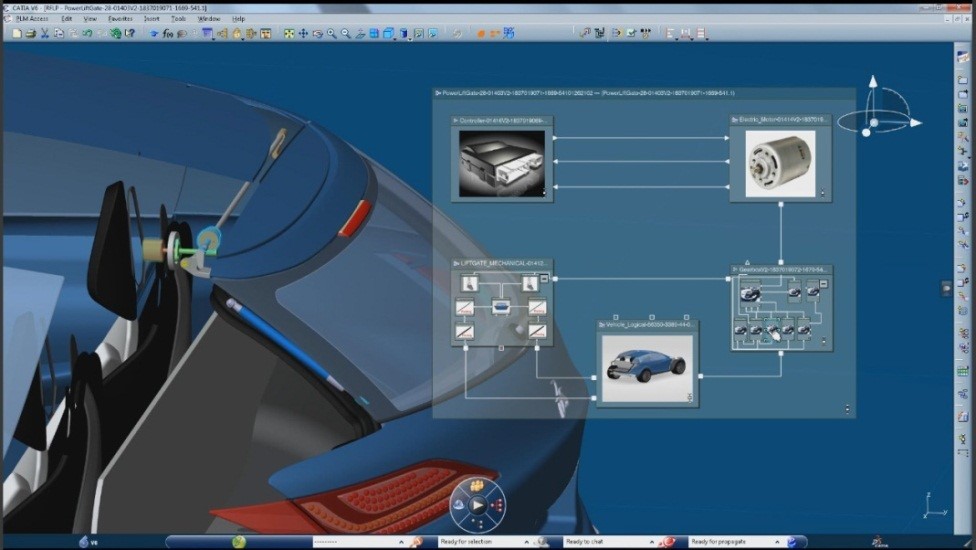

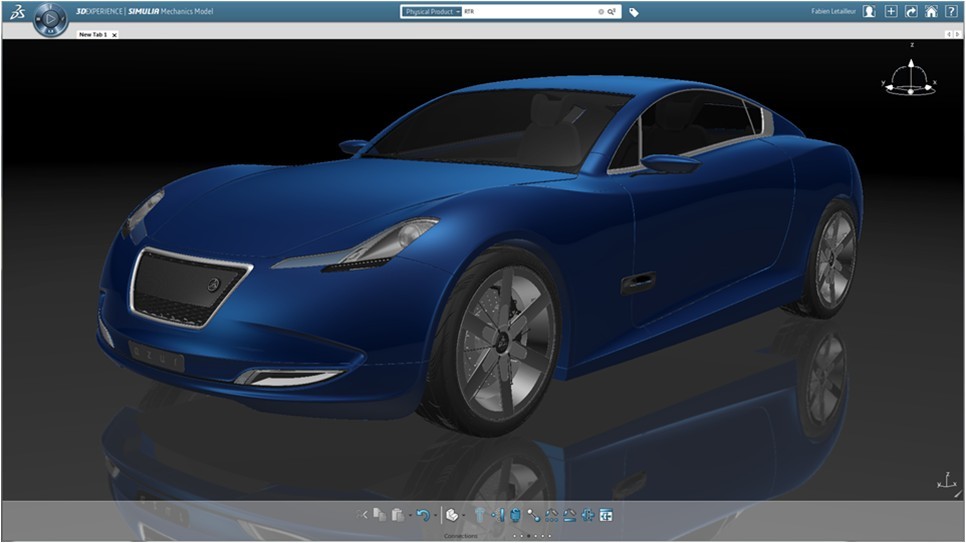

PLM systems implement and integrate knowledge engineering, system engineering, concurrent engineering, change management, and product configuration management to help automakers to release their products to market at the lowest cost and time.

Marine Industries

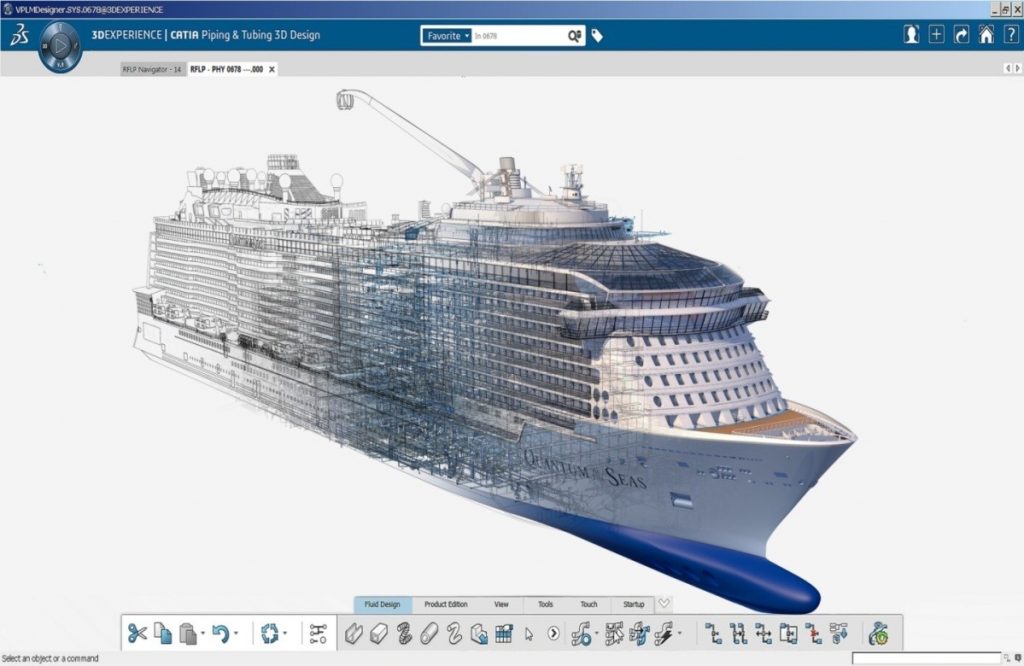

The design of products used in the marine industry, and in particular the use of fourth generation design concepts, is a highly competitive cycle in which we inevitably need sophisticated information management systems to survive.

Industrial

The use of integrated PLM and ERP systems is the only solution by which manufacturers can work more closely with their customers in a single environment, leading to the development of custom solutions, increased efficiency, and reduced costs. .

Architecture

PLM systems implement and integrate knowledge engineering, system engineering, concurrent engineering, change management, and requirement, rules, and standards management to help constructors provide their products to market at the lowest cost and shortest possible time

Technical and Engineering Services

Technical and engineering service companies using PLM and ERP systems are able to provide the best analysis services, design documentation, prototyping, production, redesign and reverse engineering to other companies and their customers.

Medical and Pharmaceutical Equipment

The use of biological simulation systems is a step that can lead to better solutions focusing on patient health and creating processes to support them to transform the process of discovery, development, production, commercialization and use of therapies.

Oil, Gas, and Petrochemistry

In the projects of this industry, there are different methods and requirements in design models, test documents, engineering documents, change management and equipment management, which can be managed in the best way by using integrated PLM and ERP systems.

Novel Technologies

The design of electronic microchips, the production of advanced semiconductor components, nanotechnology, the Internet of Things and artificial intelligence are all part of the parent industry, superior and innovative, which requires the complex infrastructure of information management systems.

- ServicesConsultingImplementationTrainingDevelopmentSupport

Consulting

Providing consulting and feasibility services in the field of implementation of standard systems and deployment of PLM and ERP systems, is done for free in Viragostar Company.

Implementation

Establishing an integrated organizational system requires the proper implementation of successful methodologies, in accordance with international standards by the implementation team.

Training

Training services based on the establishment and implementation of systems cover the entire product life cycle from the time of idea generation and management of production engineering and operational processes to the provision of after-sales service.

Development

The software and process specialists of Viragostar Technology Development Company are able to customize and develop comprehensive systems in all fields of work by using the latest technologies in the world along with local knowledge.

Support

Support services during and after the deployment and implementation of PLM and ERP systems are an important part of the requirements and needs of customers provided by Viragostar Technology Development Company.

- AcademyCoursesEventsForum

Courses

Click to view the chapters of Viragostar Company's training courses in the field of PLM and ERP systems, as well as to register for Viragostar Academy virtual courses.

Events

Upcoming events related to product lifecycle management technologies and comprehensive enterprise resource planning systems at Viragostar.

Forum

To enter the public forum in the field of PLM and ERP technologies, enter this section. Customers should also register a support ticket to the training unit in order to access private forums.

- ContentsNewsBlogArticlesMedia

News

Follow the latest developments and news in the field of PLM and ERP products in Dassault Systemes, Siemens and SAP in this section.

Blog

For the latest tips, tricks and technical experiences in using our comprehensive work systems, join the blog section.

Articles

Follow the latest technical articles in the field of PLM and ERP products in Dassault Systemes, Siemens and SAP in this section. You can also access VIP articles by preparing a special membership package.

Media

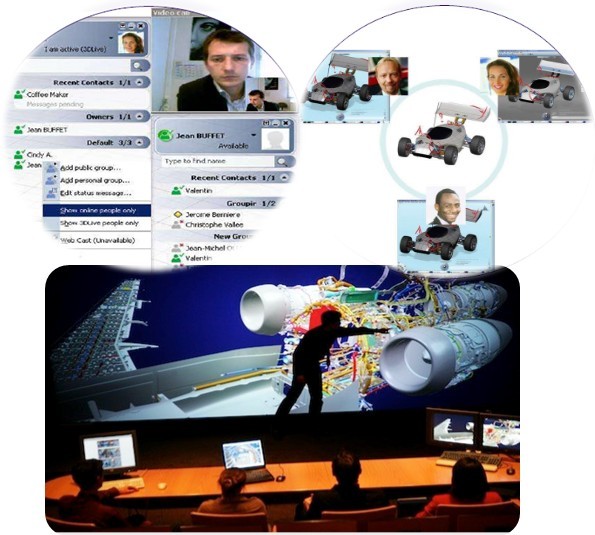

Introducing customers, presenting promotional videos, public webinars and user experiences in the field of three-dimensional and two-dimensional design in PLM software and ERP systems.

- AboutAbout UsValuesVisionContact

about us

Provide a brief history of technical and engineering activities of the DASME team and introduce Viragostar Company

Values

We care about maintaining our organizational values in relation to our customers, the community and the environment. To view the values charter of Viragostar Technology Development Company enter this section.

Vision

If you want to know about our goals and strategy for the next few years, enter this section. We pursue various goals in order to develop PLM and ERP information systems in the country's industries.

Contact

For information on the contact details of Viragostar Company, as well as the exact address and internet map for appointments or face-to-face meetings, refer to this section.

- SupportDownloadsLogin

Downloads

In the software download section, it is possible to use several free files and documents in various fields such as application standards, free 3D models and product catalogs provided by us.

Login

It is possible to use the store of products or articles and dedicated forums by entering the site. In order to receive a user account, it is necessary to complete the registration form and SMS authentication.

English

English

- ProductsDassault SystemesSiemens PLMERP SystemsOur Products

- IndustriesMarineAerospaceMarine IndustriesIndustrialArchitectureEngineeringPharmaceuticalOil & GasNovel Technologies

Marine

The aerospace and military industries face an assortment of challenges. The sensitivity involved in verifying an airplane component is much more complex than a car’s or industrial machine’s component, and no expenses are spared for creating publishable information and documents

Aerospace

PLM systems implement and integrate knowledge engineering, system engineering, concurrent engineering, change management, and product configuration management to help automakers to release their products to market at the lowest cost and time.

Marine Industries

The design of products used in the marine industry, and in particular the use of fourth generation design concepts, is a highly competitive cycle in which we inevitably need sophisticated information management systems to survive.

Industrial

The use of integrated PLM and ERP systems is the only solution by which manufacturers can work more closely with their customers in a single environment, leading to the development of custom solutions, increased efficiency, and reduced costs. .

Architecture

PLM systems implement and integrate knowledge engineering, system engineering, concurrent engineering, change management, and requirement, rules, and standards management to help constructors provide their products to market at the lowest cost and shortest possible time

Technical and Engineering Services

Technical and engineering service companies using PLM and ERP systems are able to provide the best analysis services, design documentation, prototyping, production, redesign and reverse engineering to other companies and their customers.

Medical and Pharmaceutical Equipment

The use of biological simulation systems is a step that can lead to better solutions focusing on patient health and creating processes to support them to transform the process of discovery, development, production, commercialization and use of therapies.

Oil, Gas, and Petrochemistry

In the projects of this industry, there are different methods and requirements in design models, test documents, engineering documents, change management and equipment management, which can be managed in the best way by using integrated PLM and ERP systems.

Novel Technologies

The design of electronic microchips, the production of advanced semiconductor components, nanotechnology, the Internet of Things and artificial intelligence are all part of the parent industry, superior and innovative, which requires the complex infrastructure of information management systems.

- ServicesConsultingImplementationTrainingDevelopmentSupport

Consulting

Providing consulting and feasibility services in the field of implementation of standard systems and deployment of PLM and ERP systems, is done for free in Viragostar Company.

Implementation

Establishing an integrated organizational system requires the proper implementation of successful methodologies, in accordance with international standards by the implementation team.

Training

Training services based on the establishment and implementation of systems cover the entire product life cycle from the time of idea generation and management of production engineering and operational processes to the provision of after-sales service.

Development

The software and process specialists of Viragostar Technology Development Company are able to customize and develop comprehensive systems in all fields of work by using the latest technologies in the world along with local knowledge.

Support

Support services during and after the deployment and implementation of PLM and ERP systems are an important part of the requirements and needs of customers provided by Viragostar Technology Development Company.

- AcademyCoursesEventsForum

Courses

Click to view the chapters of Viragostar Company's training courses in the field of PLM and ERP systems, as well as to register for Viragostar Academy virtual courses.

Events

Upcoming events related to product lifecycle management technologies and comprehensive enterprise resource planning systems at Viragostar.

Forum

To enter the public forum in the field of PLM and ERP technologies, enter this section. Customers should also register a support ticket to the training unit in order to access private forums.

- ContentsNewsBlogArticlesMedia

News

Follow the latest developments and news in the field of PLM and ERP products in Dassault Systemes, Siemens and SAP in this section.

Blog

For the latest tips, tricks and technical experiences in using our comprehensive work systems, join the blog section.

Articles

Follow the latest technical articles in the field of PLM and ERP products in Dassault Systemes, Siemens and SAP in this section. You can also access VIP articles by preparing a special membership package.

Media

Introducing customers, presenting promotional videos, public webinars and user experiences in the field of three-dimensional and two-dimensional design in PLM software and ERP systems.

- AboutAbout UsValuesVisionContact

about us

Provide a brief history of technical and engineering activities of the DASME team and introduce Viragostar Company

Values

We care about maintaining our organizational values in relation to our customers, the community and the environment. To view the values charter of Viragostar Technology Development Company enter this section.

Vision

If you want to know about our goals and strategy for the next few years, enter this section. We pursue various goals in order to develop PLM and ERP information systems in the country's industries.

Contact

For information on the contact details of Viragostar Company, as well as the exact address and internet map for appointments or face-to-face meetings, refer to this section.

- SupportDownloadsLogin

Downloads

In the software download section, it is possible to use several free files and documents in various fields such as application standards, free 3D models and product catalogs provided by us.

Login

It is possible to use the store of products or articles and dedicated forums by entering the site. In order to receive a user account, it is necessary to complete the registration form and SMS authentication.

English

English